|

- Forged Alloy Steel – Quenched and Tempered.

- Load rating codes stamped on each hook.

- Proper design, careful forging, and precision controlled quench and tempering gives maximum strength without excessive weight and bulk.

- Hoist hooks incorporate markings forged into the product which address two (2) QUIC-CHECK features:

-

- Deformation Indicators — Two strategically placed marks, one just below the shank or eye and the other on the hook tip, which allows for a QUIC-CHECK measurement to determine if the throat opening has changed, thus indicating abuse or overload. To check, use a measuring device (i.e. tape measure) to measure the distance between the marks. The marks should align to either an inch or half-inch increment on the measuring device. If the measurement does not meet this criteria, the hook should be inspected further for possible damage.

- Angle Indicators – Indicates the maximum included angle which is allowed between two (2) sling legs in the hook. These indicators also provide the opportunity to approximate other included angles between two slings legs.

- With Bearing: New anti-friction bearing design allows hook to rotate freely under load.

SWIVEL HOOKS

|

|

| Working Load Limit (t)* |

Weight Each (lbs.) |

Dimensions (in.) |

|||||||||||||||

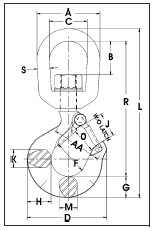

| Carbon | Alloy | A | B | C | D | F | G | H | J | K | L | M | O | R | S | AA | |

| 3/4 | 1 | .75 | 2.00 | .82 | 1.25 | 2.86 | 1.25 | .73 | .81 | .93 | .63 | 5.66 | .63 | .93 | 4.55 | .38 | 1.50 |

| 1 | 1-1/2 | 1.25 | 2.50 | 1.31 | 1.50 | 3.15 | 1.38 | .84 | .94 | .97 | .71 | 6.71 | .71 | .97 | 5.37 | .50 | 2.00 |

| 1-1/2 | 2 | 2.25 | 3.00 | 1.50 | 1.75 | 3.59 | 1.50 | 1.00 | 1.16 | 1.06 | .88 | 7.75 | .88 | 1.06 | 6.12 | .63 | 2.00 |

| 2 | 3 | 2.30 | 3.00 | 1.50 | 1.75 | 4.00 | 1.62 | 1.13 | 1.31 | 1.19 | .94 | 8.25 | .94 | 1.16 | 6.50 | .63 | 2.00 |

| 3 | 5 | 4.96 | 3.50 | 1.64 | 2.00 | 4.84 | 2.00 | 1.44 | 1.63 | 1.50 | 1.31 | 9.69 | 1.13 | 1.41 | 7.50 | .75 | 2.50 |

| 5 | 7 | 10.29 | 4.56 | 2.29 | 2.50 | 6.28 | 2.50 | 1.81 | 2.06 | 1.78 | 1.66 | 12.47 | 1.44 | 1.69 | 9.63 | 1.00 | 3.00 |

| 7-1/2 | 11 | 16.18 | 5.00 | 2.53 | 2.75 | 7.54 | 3.00 | 2.25 | 2.63 | 2.41 | 1.88 | 14.75 | 1.63 | 2.22 | 11.37 | 1.13 | 4.00 |

| 10 | 15 | 23.25 | 5.62 | 2.48 | 3.12 | 8.34 | 3.25 | 2.59 | 2.94 | 2.62 | 2.19 | 16.40 | 1.94 | 2.41 | 12.25 | 1.25 | 4.00 |

| 15 | 22 | 47.00 | 7.10 | 3.76 | 4.10 | 10.34 | 4.25 | 3.00 | 3.50 | 3.41 | 2.69 | 21.34 | 2.38 | 3.19 | 16.71 | 1.50 | 5.00 |

| — | 30 | 70.50 | 7.10 | 3.76 | 4.10 | 13.62 | 5.00 | 3.61 | 4.63 | 4.00 | 3.00 | 23.25 | 3.00 | 3.25 | 18.01 | 1.50 | 6.50 |

* NOTE: Carbon swivel hooks .75tC-15tC: proof load is 2 times working load limit. Designed with a 5 to 1 design factor.

Alloy swivel hooks 1.5tA-22tA : proof load is 2.5 times the working load limit. Designed with a 4.5 to 1 design factor.

Alloy swivel hooks 30tA: proof load is 2 times working load limit. Designed with a 4 to 1 design factor.

Dimensions for hooks 3/4 ton carbon through 22 ton alloy are for S-4320 latch kits. Dimensions for hooks 30 ton alloy are for PL latch kit.

SWIVEL HOOKS WITH BEARING

|

|

| Working Load Limit (t)* |

Dimensions (in.) |

||||||||||||||

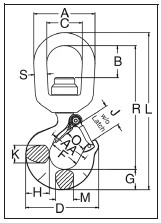

| A | B | C | D | F | G | H | J | K | L | M | O | R | S | AA | |

| 2 | 3.00 | 1.50 | 1.75 | 3.59 | 1.50 | 1.00 | 1.16 | 1.06 | .88 | 7.64 | .88 | 1.00 | 6.01 | .63 | 2.00 |

| 3 | 3.50 | 1.56 | 2.00 | 4.00 | 1.62 | 1.13 | 1.31 | 1.19 | .94 | 8.60 | .94 | 1.09 | 6.72 | .75 | 2.00 |

| 5 | 4.00 | 1.56 | 2.25 | 4.84 | 2.00 | 1.44 | 1.63 | 1.50 | 1.31 | 10.32 | 1.13 | 1.36 | 8.00 | .88 | 2.50 |

| 7 | 5.00 | 1.94 | 2.75 | 6.27 | 2.50 | 1.81 | 2.06 | 1.78 | 1.66 | 12.84 | 1.44 | 1.61 | 9.90 | 1.13 | 3.00 |

| 11 | 5.62 | 2.05 | 3.12 | 7.54 | 3.00 | 2.25 | 2.63 | 2.41 | 1.88 | 15.24 | 1.63 | 2.08 | 11.74 | 1.25 | 4.00 |

| 15 | 7.12 | 3.62 | 4.10 | 8.33 | 3.25 | 2.59 | 2.94 | 2.62 | 2.19 | 18.64 | 1.94 | 2.27 | 14.41 | 1.50 | 4.00 |

*NOTE: Proof-load is 2.5 times working load limit. Designed with a 4.5 to 1 design factor.

L-3322 is supplied with latch attached.